Intensive, housed pig farming systems, and dairy cow feedpads, standoff areas and calf rearing units are suited to pre-treatment of effluent using a two-stage pond system because they typically produce effluent high in organic matter and, in the case of piggeries, high in nitrogen and phosphorus levels.

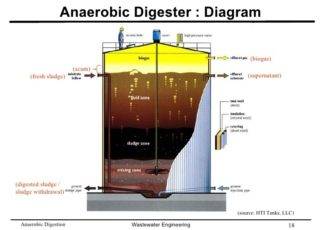

Anaerobic or First Pond

Raw effluent or waste enters the anaerobic pond. Bacteria that do not require oxygen break down organic matter, releasing carbon dioxide, ammonia and methane (visible as ‘bubbling’). Solid materials, such as undigested and non-degradable solids, sink to the pond floor forming sludge, which is removed mechanically once or twice a year. A crust of solids also typically forms on the surface.

These processes act to reduce the organic and nutrient levels before partially treated effluent enters the second, aerobic pond.

Ponds need to have the following features to encourage the activity of anaerobic bacteria:

They should be at least a depth of three metres and preferably four to five metres.

The surface area should be small.

The long axis of the pond should be perpendicular (at right angles) to the prevailing wind.

A depth of four to five metres concentrates the biological action by allowing dark, still conditions. It also helps to retain heat necessary for bacterial activity. The limitations of machinery to remove sludge usually restrict pond depth to five metres.

A small surface area minimises the area of effluent in contact with oxygen at the pond surface. It also reduces heat loss, promotes the formation of an undisturbed surface layer and minimises the quantity of rainfall entering the system.

Building the pond so the long axis is perpendicular to the prevailing wind maximises the settlement of solids as it reduces effluent movement. If shelter is provided from the wind then orientation is less important.

The by-products of anaerobic digestion generally produce more offensive odours than aerobic digestion. Volatile fatty acids, phenols and hydrogen sulphide produce strong odours that may be detected a considerable distance from ponds. Other compounds released are odourless (e.g. methane). Proper management of ponds should keep odour problems to a minimum.

The activity of anaerobic digestion typically removes about 70% of the biochemical oxygen demand of raw effluent entering the system. The level of nutrients flowing into the second pond is also reduced.

Aerobic or Second Pond

The aerobic pond encourages the growth of algae which produce oxygen in excess to their requirements. This excess oxygen is used by aerobic bacteria (those that need oxygen to survive) to further break down organic matter. Aeration of the water by wind can also increase oxygen levels.

To encourage the activity of algae and aerobic bacteria aerobic ponds need to have the following features:

They should be no more than 1200 millimetres deep.

The surface area should be large.

The shallow depth allows sunlight to penetrate, allowing algae to grow and reduces the occurrence of anaerobic conditions such as those present in the still, depths of anaerobic ponds. Wind or the use of mechanical aerators can also effectively mix effluent allowing oxygenated water to move to the bottom of the pond and further enhance aerobic bacterial activity. Some anaerobic bacteria will still be present in low oxygenated areas of the pond.

A large surface area increases algal populations which results in greater aerobic bacteria populations. Where effluent volume is high, two aerobic ponds may be necessary rather one pond with a very large surface area. In this case the flow from the anaerobic pond should be split between the two (i.e. have the aerobic ponds working in parallel).

The following processes occur in the aerobic pond:

Breakdown of most of the remaining dissolved organic matter near the pond surface.

Further anaerobic treatment through the separation, dissolving and digestion of organic material.

A reduction in the amount of disease-causing micro-organisms.

20% to 30% of the ammonia contained within the effluent is released to the air.

Solids separate out, including undigested material and non-degradable solids, and settle as sludge.

Two-stage pond systems have traditionally been used to treat dairy and pig waste which is then discharged to a waterway. Discharging to a waterway is not recommended farm management practice, and in some areas is banned, due to the harmful environmental impact on streams, rivers and lakes.

However, there is a case for using two-stage pond systems to pre-treat effluent that is high in organic matter and nutrient levels. After pre-treatment effluent can then be held in storage ponds or tanks and discharged to land when conditions are suitable.